Why measure gloss?

Gloss is an aspect of the visual perception of objects that is as important as colour when considering the psychological impact of products on a

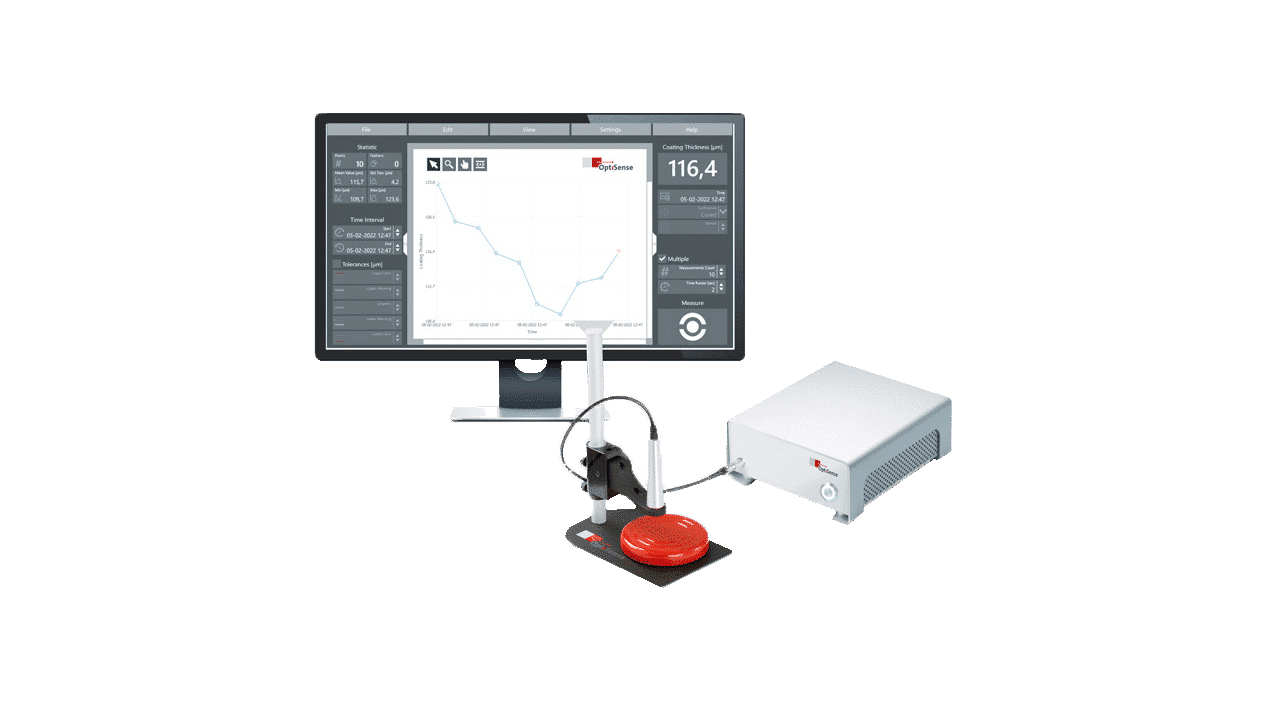

The OptiSense Lab laser models are used for a wide range of coatings on metallic and non-metallic substrates. With their tiny measuring spot the slim laser sensors are particularly suitable for coating thickness testing on delicate small parts, corners and edges. A special version with an extra short working distance allows to measure in very confined spaces or on coatings containing high amounts of metal. All OptiSense laser models are eye-safe thanks to the patented LARES® technology.

LED sensors feature a larger measuring spot making them ideal for freehand measurements on rough surfaces. The LED-R model is particularly suited for components made of plastic or rubber. The sensor head of all OptiSense Lab models is detached from the control unit and connected with a flexible cable. The desktop controller is conveniently placed close to the operating PC while the lightweight, ergonomically designed sensor can be guided precisely and effortlessly to the component without touching or damaging the sensitive coating.

The PaintChecker Lab LED-B is designed for contactless testing of freshly applied powder coatings prior to burn-in. It measures the still soft powder layer independent of color and type on substrate such as metal, wood, glass or plastic. The shrinkage during burn-in is taken into account. Simple measurements in the lab with the small desktop unit allow the powder application to be optimized in such a way that the very cost-intensive rework, especially with large components, can be avoided.

Gloss is an aspect of the visual perception of objects that is as important as colour when considering the psychological impact of products on a

Identify the surface that you wish to measure. Is it a flat surface? If so, it can be measured with a traditonal glossmeter. Curved surfaces

RSpec is the peak reflectance measured over a very narrow angular band in the specular direction (+/-) 0.0991º. RSpec is very sensitive to any texture