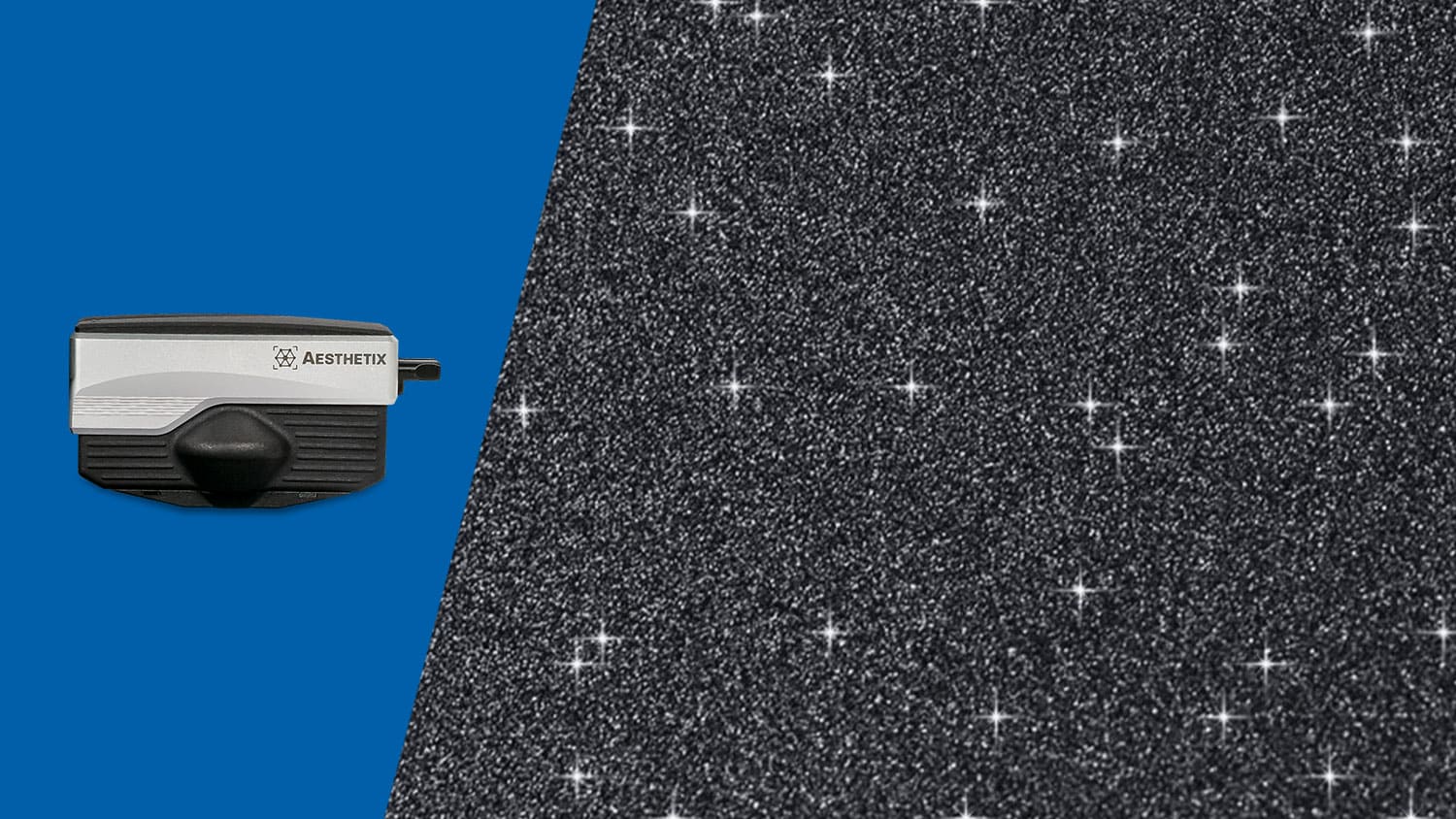

Aesthetix®: The Ultimate Surface Finish Solution

- Fully characterise all aspects of appearance perception - Why does this matter?

- Modular solution: Surface Brilliance | Texture | Effect Finish

- Aesthetix® can be used in-laboratory, portable in-field, inline in the production environment or as part of a Cobot / Robot solution

- Measures flat surfaces, curved parts and small surface areas

- Affordable technology starts at $7,500