Appearance & Measurement Experts since 1986

Home » Furniture

Home » Furniture

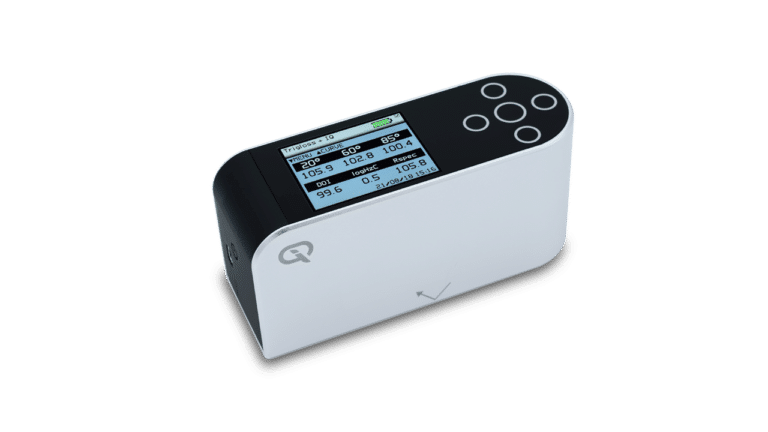

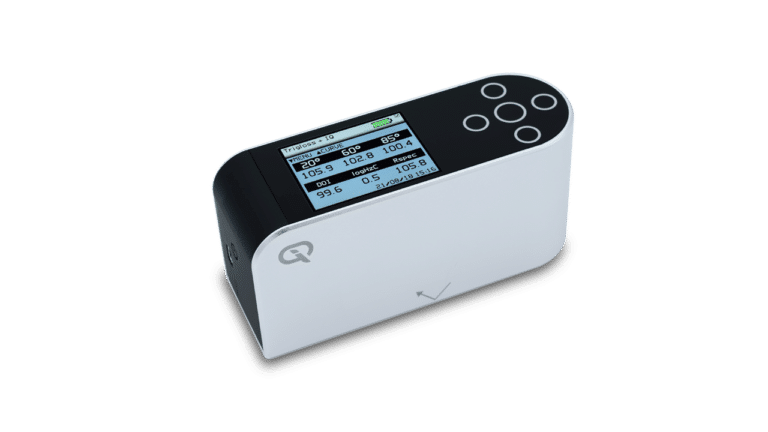

The Rhopoint Aesthetix is a state-of-the-art tool tailored for the high-quality furniture industry, providing precise measurements of surface attributes such as gloss, texture, sparkle, graininess, and scratch resistance. Its ability to measure small or curved parts and its compatibility with custom 3D-printed jigs and collaborative robots (cobots) ensures consistent quality control and efficient production workflows.

The Rhopoint Aesthetix is a transformative solution for the high-quality furniture industry, offering advanced measurement capabilities combined with cobot-driven automation and custom jigs to ensure consistent quality across all components while enhancing efficiency in production workflows.

⁂