Why measure gloss?

Gloss is an aspect of the visual perception of objects that is as important as colour when considering the psychological impact of products on a

$5,955

The Rhopoint IQ Flex 20 quantifies surface quality problems such as orange peel and haze that are invisible to a standard glossmeter. It profiles how light is reflected from a surface.

Previously only available for measuring flat surfaces, this technology is now available in a new format specifically designed for curved surfaces, as well as small and delicate parts. Flex 20 gloss measurements are fully compatible with existing Rhopoint IQ results.

The Rhopoint IQ Flex 20 can measure:

The Rhopoint IQ Flex 20 quantifies surface quality problems such as orange peel and haze that are invisible to a standard glossmeter. It profiles how light is reflected from a surface.

Combined gloss, haze and orange peel (DOI/RIQ values) information has made the IQ essential for controlling appearance finish. The Rhopoint IQ Flex 20 brings this technology to a new format specifically designed for curved surfaces, as well as small and delicate parts.

Conventional gloss instruments are suited to large flat test areas, as curved surfaces will cause errors. The small footprint of the IQ Flex 20 makes it much more effective on curved surfaces than a conventional glossmeter; its compact size and shape also allows access to difficult to reach areas.

The Rhopoint IQ Flex 20 can be customised with magnetically attached adaptor plates. These can be easily interchanged for different applications. The measurement spot size of these adaptor plates can be reduced to as low as 2mm.

Bespoke 3D printed adaptor jigs for repeatable control of curved surfaces (requires a .dxf drawing of the part to be measured).

Easy customisation for every application with bespoke measuring adaptors.

The Rhopoint IQ Flex 20 can be customised with magnetically attached adaptor plates to allow for the measurement of irregular surfaces. These can be easily interchanged for different applications.

Gloss has been defined as ‘The attribute of surfaces that causes them to have shiny or lustrous, metallic appearance.’

Manufacturers design their products to have maximum appeal: from highly reflective car body panels to glossy household appliances or matt finish automotive interior trim.

This is especially noticeable where parts may be produced by different manufacturers or factories but will be placed adjacent to one another to create the finished product.

Gloss can also be a measure of the quality of the surface, for instance a drop in the gloss of a coated surface may indicate problems with its cure, leading to other failures such as poor adhesion or lack of protection for the coated surface.

The gloss of a surface can be greatly influenced by a number of factors, for example the smoothness achieved during polishing, the amount and type of coating applied or the quality of the substrate.

It is for these reasons that many manufacturing industries monitor the gloss of their products, from cars, printing and furniture to food, pharmaceuticals and consumer electronics.

It is important therefore that gloss levels are achieved consistently on every product or across different batches of products.

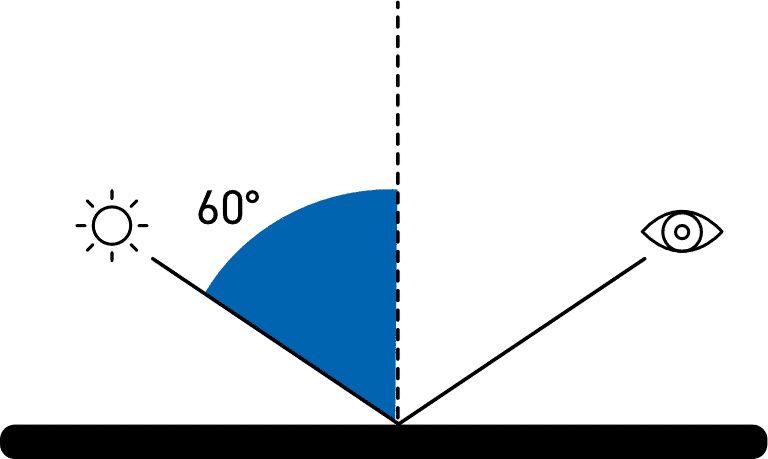

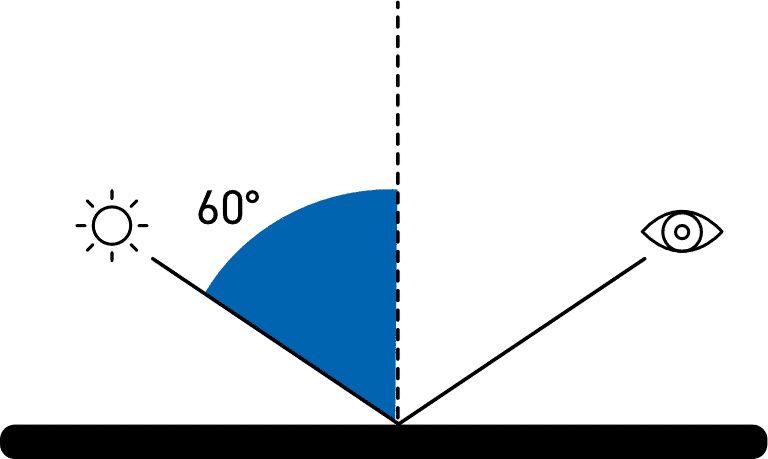

ISO 2813 and ASTM D523 (the most commonly used standards) describe three measurement angles to measure gloss across all surfaces.

Gloss is measured in gloss units (GU) and is traceable to reference standards held at NIST (USA).

All gloss levels can be measured using the standard measurement angle of 60°. This is used as the reference angle with the complimentary angles of 85° and 20° often used for low and high gloss levels respectively.

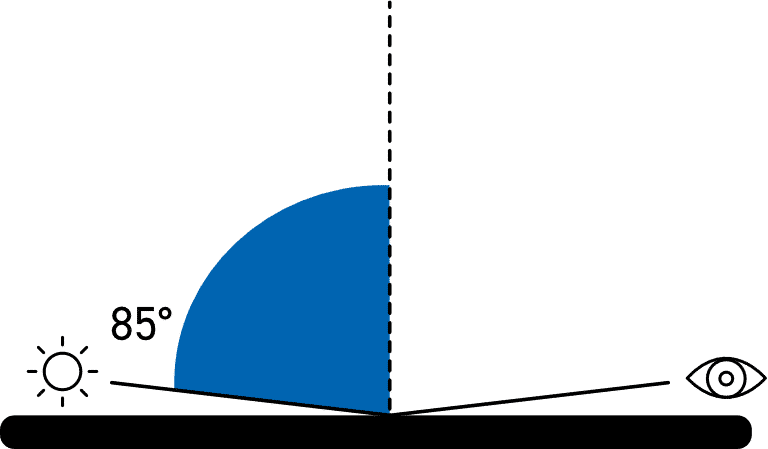

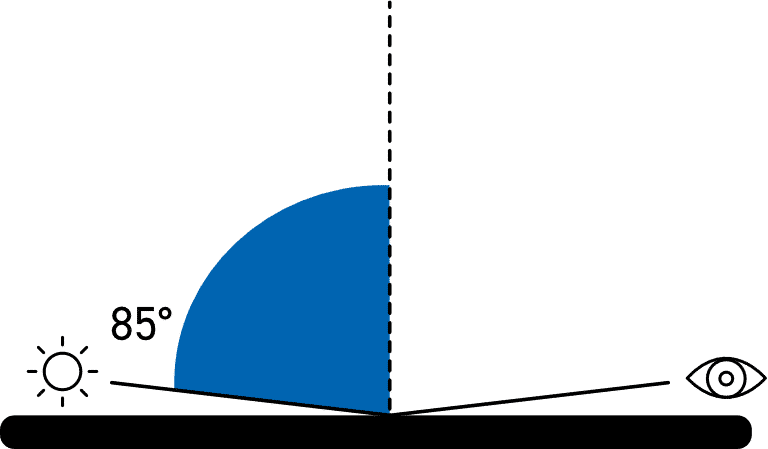

For improved resolution of low gloss a grazing angle of 85° is used to measure the surface. This angle is recommended for surfaces which measure less than 10GU when measured at 60°.

This angle also has a larger measurement spot which will average out differences in the gloss of textured or slightly uneven surfaces.

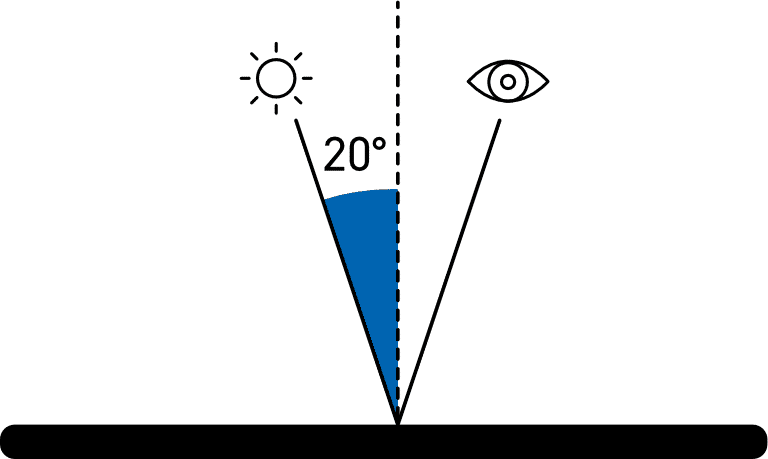

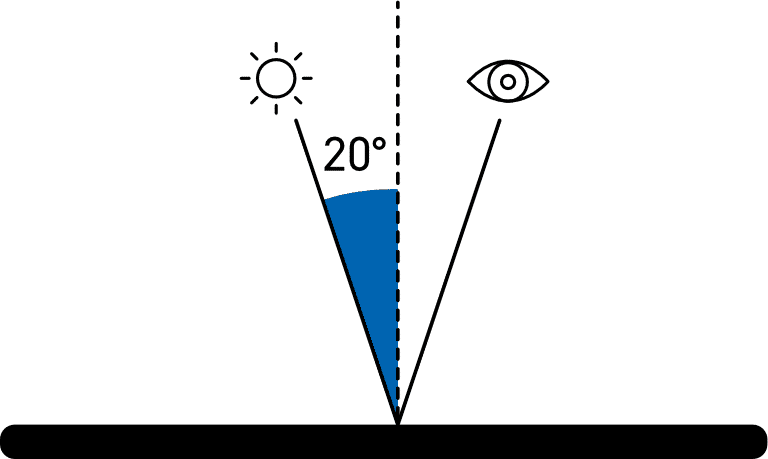

The acute measurement angle of 20° gives improved resolution for high gloss surfaces. Surfaces that measure 70GU and above at the standard angle of 60° are often measured with this geometry.

The 20° angle is more sensitive to haze effects that affect the appearance of a surface.

This measuring angle is in accordance with the ISO 2457 standard for the gloss measurement of plastic films and solid plastic parts as well as according to the standard ASTM C346 for the gloss measurement of ceramics

All gloss levels can be measured using the standard measurement angle of 60°. This is used as the reference angle with the complimentary angles of 85° and 20° often used for low and high gloss levels respectively.

For improved resolution of low gloss a grazing angle of 85° is used to measure the surface. This angle is recommended for surfaces which measure less than 10GU when measured at 60°.

This angle also has a larger measurement spot which will average out differences in the gloss of textured or slightly uneven surfaces.

The acute measurement angle of 20° gives improved resolution for high gloss surfaces. Surfaces that measure 70GU and above at the standard angle of 60° are often measured with this geometry.

The 20° angle is more sensitive to haze effects that affect the appearance of a surface.

To quantify haze, distinctness of image, reflected image quality and other surface texturing please consider the Rhopoint IQ.

In the coatings industry, this microscopic surface texture is often due to poorly dispersed raw materials, incompatible raw materials or oxidisation and weathering. For polished metal surfaces, haze is often associated with polishing marks or chemical residue.

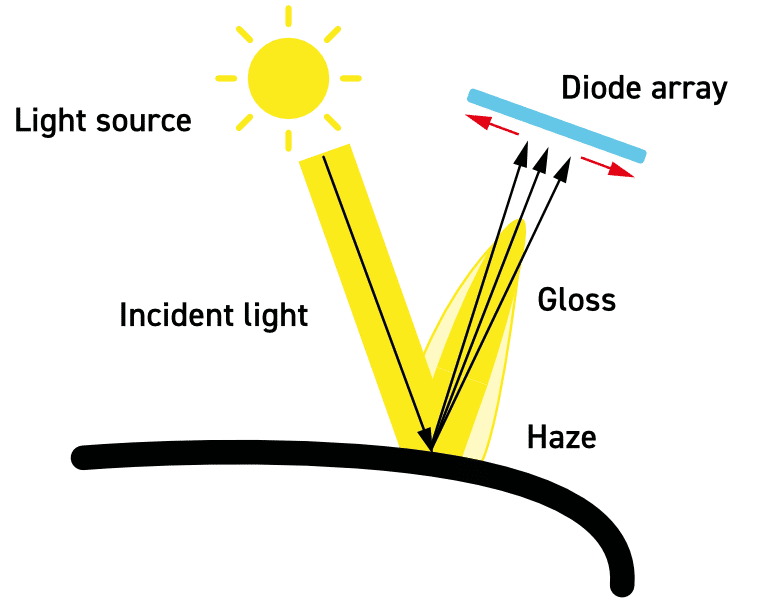

Haze is light that has been reflected by small surface structures adjacent to the main specular component.

Reflectance haze – An optical effect caused by microscopic texture or residue on a surface.

Reflection haze is an optical phenomenon usually associated with high gloss surfaces.

It is a common surface fault that reduces appearance quality. A hazy surface has a visibly shallower reflection with a milky finish and halos appear around reflections of strong light sources.

No Haze, deep reflection

High Haze, ‘shallow’ finish

A high gloss finish with haze exhibits a milky finish with low reflective contrast, reflected highlights and lowlights are less pronounced.

Low Haze

Higher Haze

On surfaces with haze, halos are visible around the reflections of strong light sources.

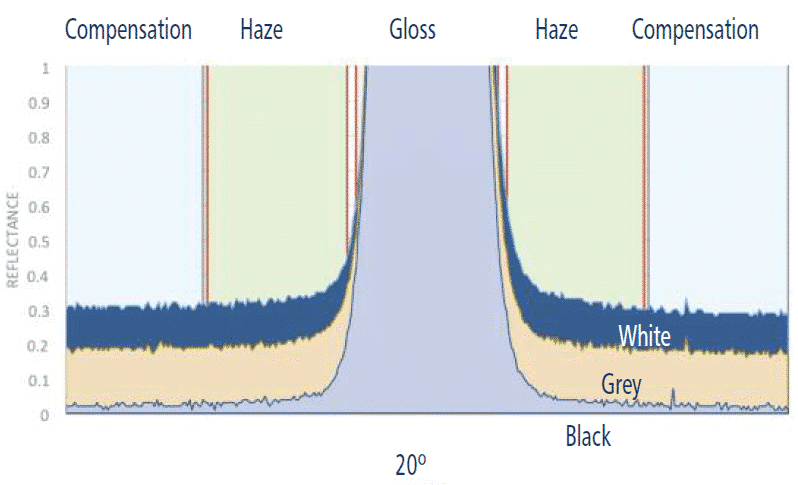

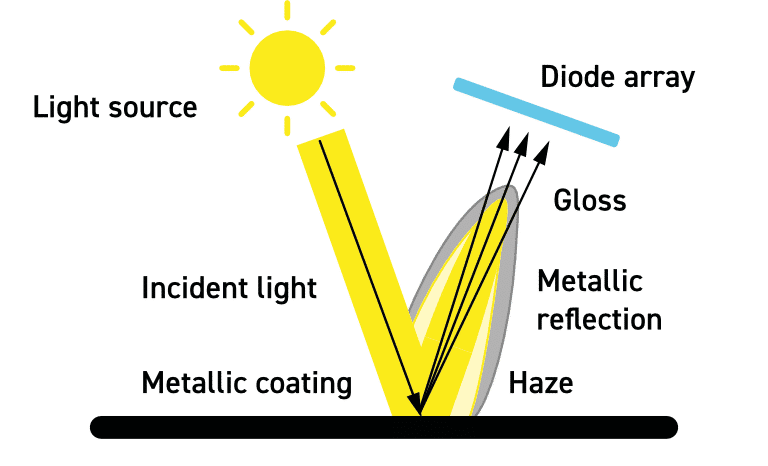

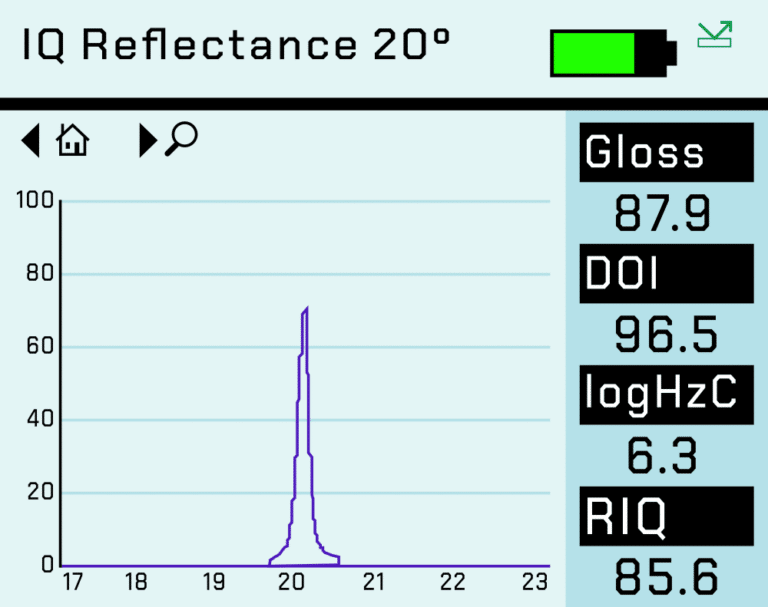

The IQ Flex 20 uses a 512 element linear diode array which profiles reflected light in a large arc from 14° to 27°. The instrument processes this high resolution data, selecting individual elements within the array that equate to the angular tolerences outlined in international measurement standards.

A major advantage of the IQ Flex 20 is that it automatically compensates for curved or textured sample surfaces by virtually adjusting the measurement position. Conventional gloss- hazemeters have fixed optics which can make measurement unreliable as any sample curvature will reflect light away from the centre of the measurement sensor causing errors.

The IQ Flex 20 automatically adjusts the sensor position by detecting the peak of the reflected light. The laws of reflection state that the incident angle is equal to the reflection angle thus the peak equates exactly to the 20° gloss angle.

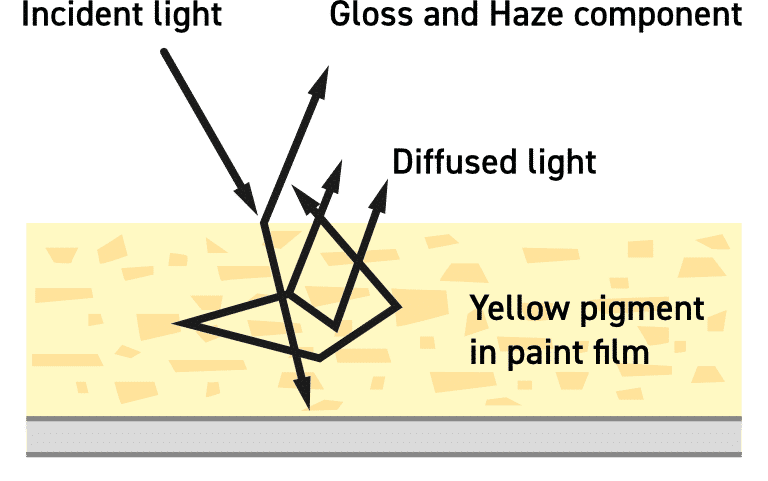

Reflection haze is caused by micro texture on a surface which causes a small amount of light to be reflected adjacent to the gloss angle.

For white surfaces, bright colours and metallics, a certain amount of diffuse light, reflected from within the material, is also present in this region.

This diffuse light exaggerates the haze signal for these surfaces causing higher than expected readings.

* Only enabled when the instruments is set to haze measuring mode of ASTM E430

For non metallic surfaces, the diffuse component is Lambertian: it is equal in amplitude at all angles in relation to the sample surface. Conventional gloss-hazemeters measure diffuse reflection using a luminosity sensor positioned away from the gloss angle. Luminosity is subtracted from the haze signal allowing metallic surfaces to be measured independently of their colour.

An advantage of the IQ Flex 20 is that unlike a conventional instrument, compensation is calculated using a region adjacent to the haze angle. This technique gives compatible readings on solid colours but also compensates for directional reflection from metallic coatings and speciality pigments.

The Rhopoint IQ Flex 20 quantifies surface quality problems that are invisible to a standard glossmeter.

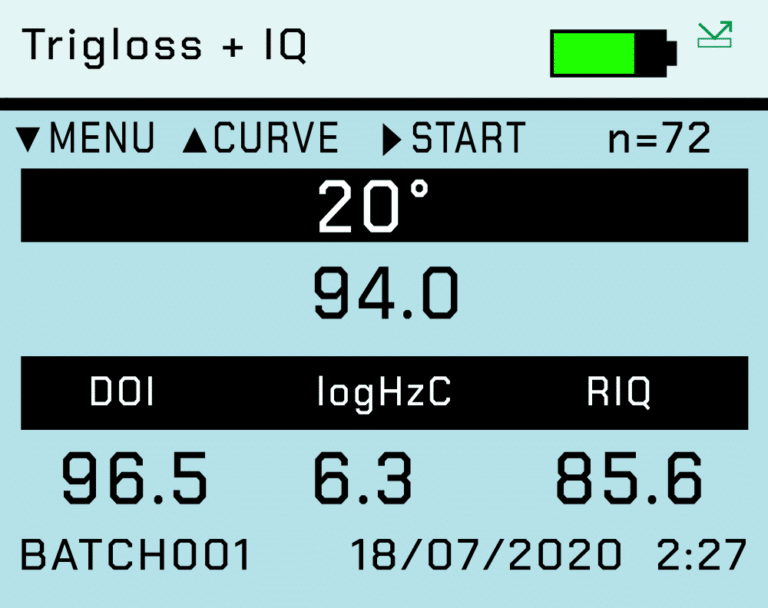

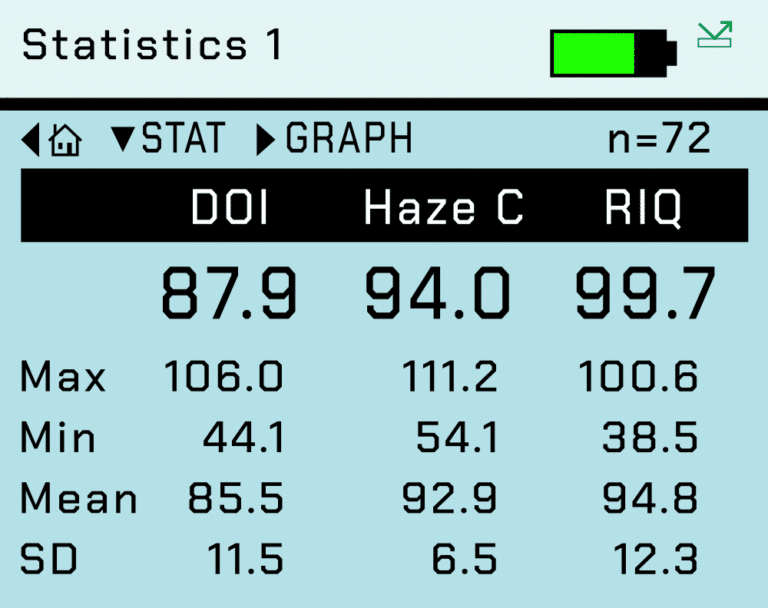

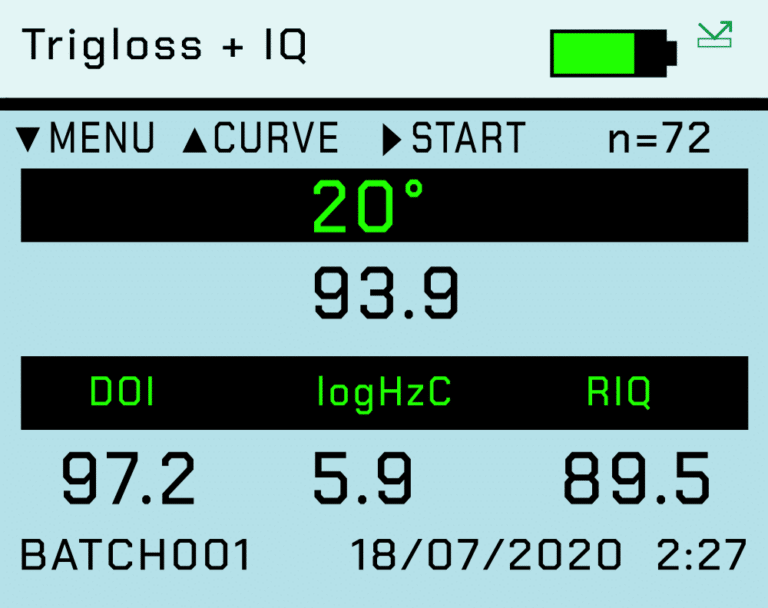

RIQ is used to quantify effects such as orange peel and surface waviness. This new parameter gives higher resolution results compared to Distinctness of Image (DOI) measurement and better mimics human perception of surface texture, especially on high quality finishes.

Symptoms of Poor RIQ: Orange peel, brush marks, waviness or other structures visible on the surface. Reflected images are distorted.

Causes: Application problems, incorrect coating flow, coating viscosity too high/low, sag or flow of coating before curing, incorrect particle size/distribution, overspray, improper flash/re-coat time, inter coat compatibility, incorrect cure times or cure temperature.

The instrument compensates for reflection from within the coating for highly reflective pigments, metallic coatings and speciality pigments, allowing the haze of any painted surface to be measured.

A measure of how clearly a reflected image will appear in a reflective surface.

An optical effect caused by microscopic texture or residue on a surface.

Visible Symptoms: A milky finish is apparent on the surface with a loss of reflected contrast. Halos and patterns can be seen around reflections of high intensity light sources.

Causes: Poor dispersion, raw material incompatibility, additive migration, vehicle quality, stoving/drying/ curing conditions, polishing marks, fine scratches, ageing, oxidisation or poor cleanliness/surface residue.

Haze is a common problem associated with coatings and polished materials. Surfaces with haze have a milky finish with a shallow reflected image. This important characteristic is directly measured with the Rhopoint IQ Flex 20.

Designed for the measurement of small and curved surfaces.

Easy to control and take measurements

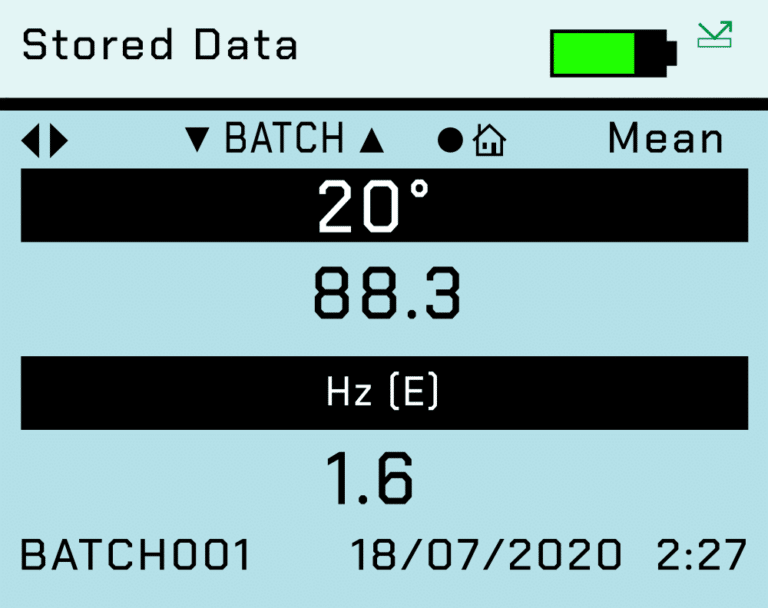

User definable batch names and batch sizes for quicker and more efficient reporting

Single button push to initiate a defined number of measurements

Fast measurement of all parameters and instantly transmit measured readings.

Simultaneous measurement of all parameters, date and time stamped.

Displays full statistics for the number of readings in the current batch.

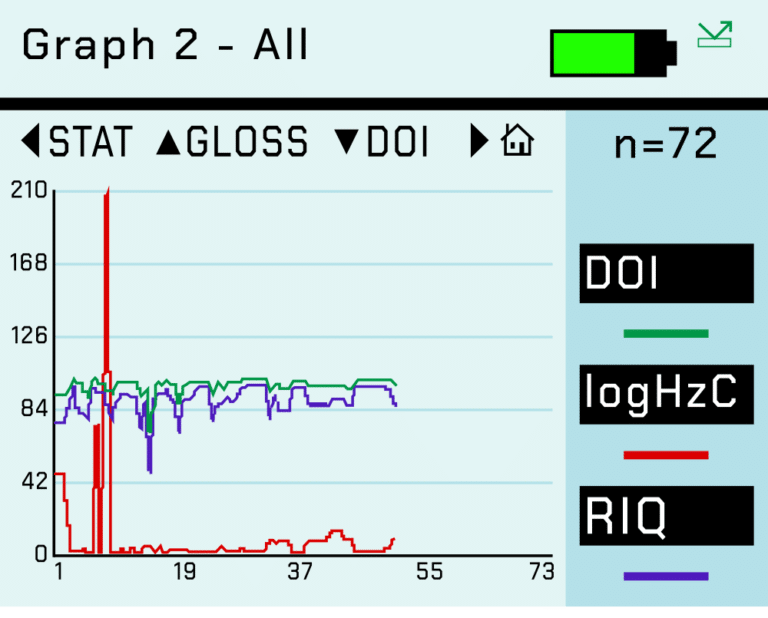

Graphical reporting for quick trend analysis.

Pass / Fail parameters can be defined for instant identification of nonconformances.

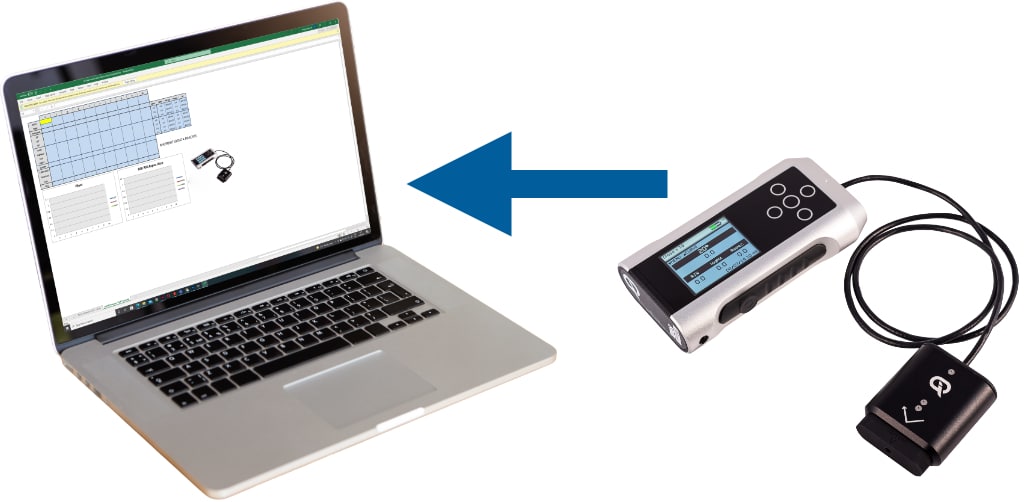

Different types of surface textures produce identifiably shaped reflectance profile. This goniophotometric data can be downloaded to a PC for further analysis and comparison via the USB cable or Bluetooth data widget.

View and inspect data saved on the instrument.

Full on-board statistics with graphical trend analysis and reporting.

USB connection to PC instantly recognises the device as a drive location which facilitates the quick transfer of .csv files using Windows Explorer or similar.

Instantly transmit measured readings directly to programs such as MS Excel on your PC / tablet to greatly simplify the reporting process.

The included software provides an easy means to measure, import and compare data and export the measurements into several other file formats, e.g. PDF, Excel® or CSV.

Sample curvature naturally reflects light away from the measurement sensor. This can be compensated by using a smaller measurement spot which is less affected by the curvature. However, on highly curved surfaces readings should be used comparatively i.e. the same spot on similar shaped samples and is therefore ideal for comparing batch to batch consistency.

| IQ Flex 20 | 4mm Reduced Spot Size Adaptor | 2mm Reduced Spot Size Adaptor | Curved Part Adaptor | Custom 3D Printed Adaptor | ||

|---|---|---|---|---|---|---|

| Repeatability | Flat Surface | Excellent | Excellent | Excellent | Excellent | N/A |

| Large radius curved e.g. car body | Good | Good | Good | Good | Excellent | |

| Cylinder >20mm ø | Poor | Poor | Poor | Good | Excellent | |

| Cylinder <20mm ø | Not recommended | Not recommended | Not recommended | Poor | Varies according to application | |

| Small flat parts >10 x 10mm | Excellent | Excellent | Excellent | Not recommended | Excellent | |

| Small flat parts <10 x 10mm | Poor | Varies according to application | Varies according to application | Not recommended | Excellent | |

| Complex shapes (curved in both directions | Not recommended | Not recommended | Not recommended | Not recommended | Excellent | |

| Correlation to standard glossmeter readings by gloss level | Flat surface – high gloss >50GU at 20° | Excellent | Excellent | Excellent | Excellent | N/A |

| Flat surface – mid gloss 30-50GU at 20° | Excellent | Good | Good | Excellent | N/A | |

| Flat surface – low gloss <20 at 20° | Excellent | Good | Not recommended | Excellent | N/A | |

| Correlation to standard glossmeter readings by sample shape | Large radius curved (car body) | Good | Good | Good | Good | Excellent |

| Cylinder >20mm ø | Good | Good | Good | Good | Excellent | |

| Cylinder >20mm ø | Comparative reading | Comparative reading | Comparative reading | Comparative reading | Comparative reading | |

| Cylinder <20mm ø | Not recommended | Not recommended | Not recommended | Poor | Varies according to application | |

| Small flat parts | Excellent areas >8mm x 8mm | Good >4mm x 4mm | High gloss: Good Areas >2mm x 2mm Poor for low gloss finishes | Not recommended | Excellent | |

| Complex shapes (curved in both directions) | N/A | N/A | N/A | N/A | N/A |

ISO2813 recommends surfaces measuring mid to low gloss finishes using 60° and 85°. Is the Flex 20 suitable or measuring these surfaces?

60° and 85° give greater resolution of measurement at these gloss levels (small visible differences in finish = a large difference in gloss value).

Whilst 20° has a smaller measurement resolution, visible differences in gloss can be quantified with the Flex 20.

The measuring head should only be connected to the instrument for measuring larger flat surfaces. It is recommended to connect the instrument to the measuring head using the cable for ease and stability of measurement.

Custom adaptors will increase the repeatability of measurement for irregular shaped objects, curved surfaces or small parts.

Curved part adaptors should be used for the measurement of all cylindrical objects.

For accurate measuring calibrating the IQ Flex 20 every day, when changing between standard head and 2/4mm adaptor is essential.

| Measuring less than 100 GU (plastics and coatings) | Measuring polished metals >100GU | |

|---|---|---|

| Standard spot size | Calibrate on black tile every shift (8 Hours) MUST BE RE-CALIBRATED with standard spot size adaptor when switching from small spot size measurement. | Calibrate on optional mirror tile (if required) MUST BE RE-CALIBRATED with standard spot size adaptor when switching from small spot size measurement. |

| Small spot size | Calibrate with small spot size adaptor (8 Hours) MUST BE RE-CALIBRATED with small spot size adaptor when switching from standard spot size measurement. | Calibrate on optional mirror tile (8 Hours) MUST BE RE-CALIBRATED with small spot size adaptor when switching from standard spot size measurement. |

IQ Flex 20 with standard spot size adaptor

IQ Flex 20 with calibration tile

The DOI, Haze and RSPEC values measured by the Rhopoint IQ Flex 20 allow the user to quantify and control the surface textures that reduce the perceived quality of manufactured products.

| Order Codes - adaptors | ||

|---|---|---|

| Rhopoint IQ Flex 20 | A6000-016 | |

| Adaptor for reduced spot size (4mm) | B6000-501/2 | |

| Adaptor for reduced spot size (2mm) | B6000-502/2 | |

| Curved part adaptor | M6000-504/NEW | |

| Customer adaptor (requires drawing of the part to be measured in .dxf format) | M6000-505 | |

| Product | Instrument Specifications | ||

|---|---|---|---|

| Gloss / 20 ̊ Gloss | Ranges (GU) | 0-100 / 100-2000 | |

| Repeatability | 0.2 (GU) / 0.2% | ||

| Reproducibility | 0.5 (GU) / 0.5% | ||

| Resolution (GU) | 0.1 | ||

| Measurement area | 6mm x 6.4mm | ||

| Standards | SO 2813, ASTM D523, ISO 7668, ASTM D2457, DIN 67530, JS Z 8741 | ||

| Calibration Standard | Traceability: NIST traceable, Uncertainty: 1.1GU | ||

| RSPEC | Peak specular reflectance | 20 ̊ ±0.09905 ̊ | |

| Measurement range | 0GU - 2000GU | ||

| Haze | Near specular reflectance | Measured at 17.2 ̊ - 19 ̊, 21 ̊ - 22.8 ̊ | |

| Switch-able between | Haze Units (HU) and Log Haze Units(LogHU) | ||

| Resolution | 0.1HU | ||

| Repeatability | ±0.5HU | ||

| Reproducibility | ±1.5HU | ||

| Standards | ASTM E430 | ||

| RIQ | Resolution | 0.1 | |

| Repeatability | ±0.2 | ||

| Reproducibility | ±0.5 | ||

| Measurement Range | 0 - 100 | ||

| DOI | Resolution | 0.1 | |

| Repeatability | ±0.2 | ||

| Reproducibility | ±0.5 | ||

| Measurement Range | 0 - 100 | ||

| Standards | ASTM E430 | ||

| Instrument Specification | Power | Rechargeable lithium ion, 6 hours operation 4,000+ readings per charge | |

| Recharge time | Mains charger: 4hrs | ||

| Memory | 8MB = 999 readings | ||

| Dimensions | 150mm (H) x 79mm (W) x 34mm (D) - without head | ||

| Packed dimensions | 180mm (H) x 330mm (W) x 280mm (D) | ||

| Weight | 550g | ||

| Packed weight | ≈1.5kg | ||

| Commodity code | 9027 5000 | ||

Free extended 2 year warranty: Requires registration at www.rhopointinstruments.com/help-services/forms-feedback/instrument-registration/ within 28 days of purchase. Without registration, 1 year standard warranty applies.

Guaranteed for the life of the instrument.

Fast and economic service via our global network of accredited calibration and service centres. Please visit www.rhopointinstruments.com/help-services/calibration-servicing/ for detailed information.

Gloss is an aspect of the visual perception of objects that is as important as colour when considering the psychological impact of products on a

Identify the surface that you wish to measure. Is it a flat surface? If so, it can be measured with a traditonal glossmeter. Curved surfaces

RSpec is the peak reflectance measured over a very narrow angular band in the specular direction (+/-) 0.0991º. RSpec is very sensitive to any texture

Please note, this is NOT a quotation, just a confirmation of the price when purchased in the UK exclusive of VAT/duties